Typical Drawer Box Installation for Small Desk Drawers

*This post contains affiliate links.

Afterwards because several options for how I wanted to employ this space between the closets in the guest bedroom, I finally settled on building a small-scale DIY writing desk with a drawer. This is a very easy and relatively quick building project. I got this basic build done in one afternoon/evening. If you're pretty new to DIY article of furniture building, and want to try your mitt at a pretty simple build, this is a nifty piece to try.

I all the same need to decide how I desire to finish the desk-bound (paint? stain?). Right at present, I'm leaning towards stain, but we'll see.

This desk is 30″h 10 48″westward x 20″d. So let me start from the first and show you how I built this simple petty writing desk-bound, and of course, you could adjust the measurements to make the desk exactly the size you demand for your particular room.

How To Build The Desk Base

The base of the desk was made using 1″ x 4″ lumber, and i.75″ x i.75″ square dowels. I cut the pieces as follows, only of form, these tin can exist adjusted to make the desk whatsoever size you need.

- Two side aprons cutting to 15 i/ii inches long using 1″ x 4″ lumber

- One back apron cutting to 42 1/two inches long using one″ ten four″ lumber

- Ane front apron cut to 42 five/8 inches long, and then cutting into 3 pieces — 2 small, stationary apron pieces that are 8 inches long, and the rest will be used equally the drawer front, using 1″ x 4″ lumber (Note: If you're going to stain the desk-bound, make sure this piece is cutting and then that the grain of the wood is continuous from ane end to the other.)

- Iv legs cut to 29.25 inches long, using 1 3/four″ square dowels

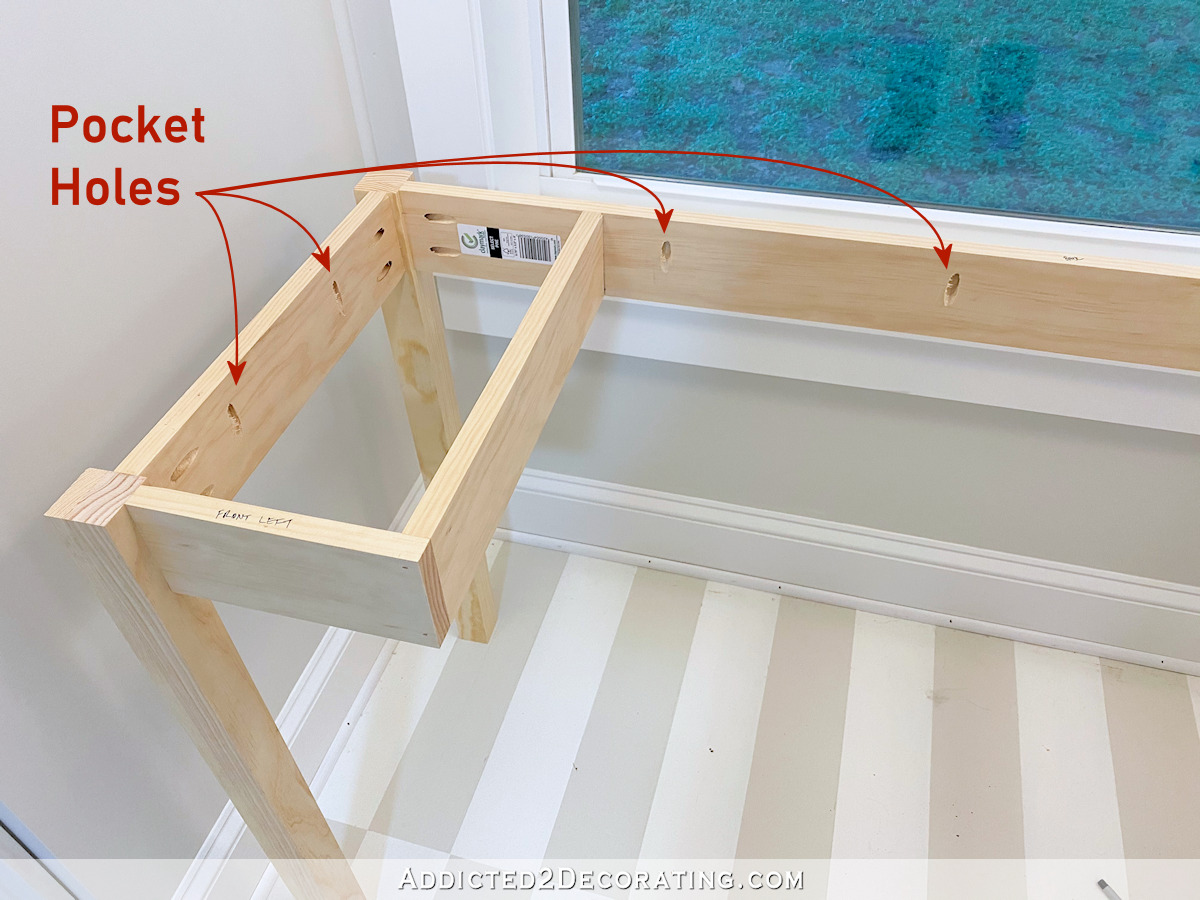

Using my Kreg Pocket Hole Jig, I drilled pocket holes into the sides of all of the apron pieces.

Here'due south how those looked with all of the pocket holes drilled. Y'all'll discover that the center front end piece (i.e., the drawer front end) does not need pocket holes.

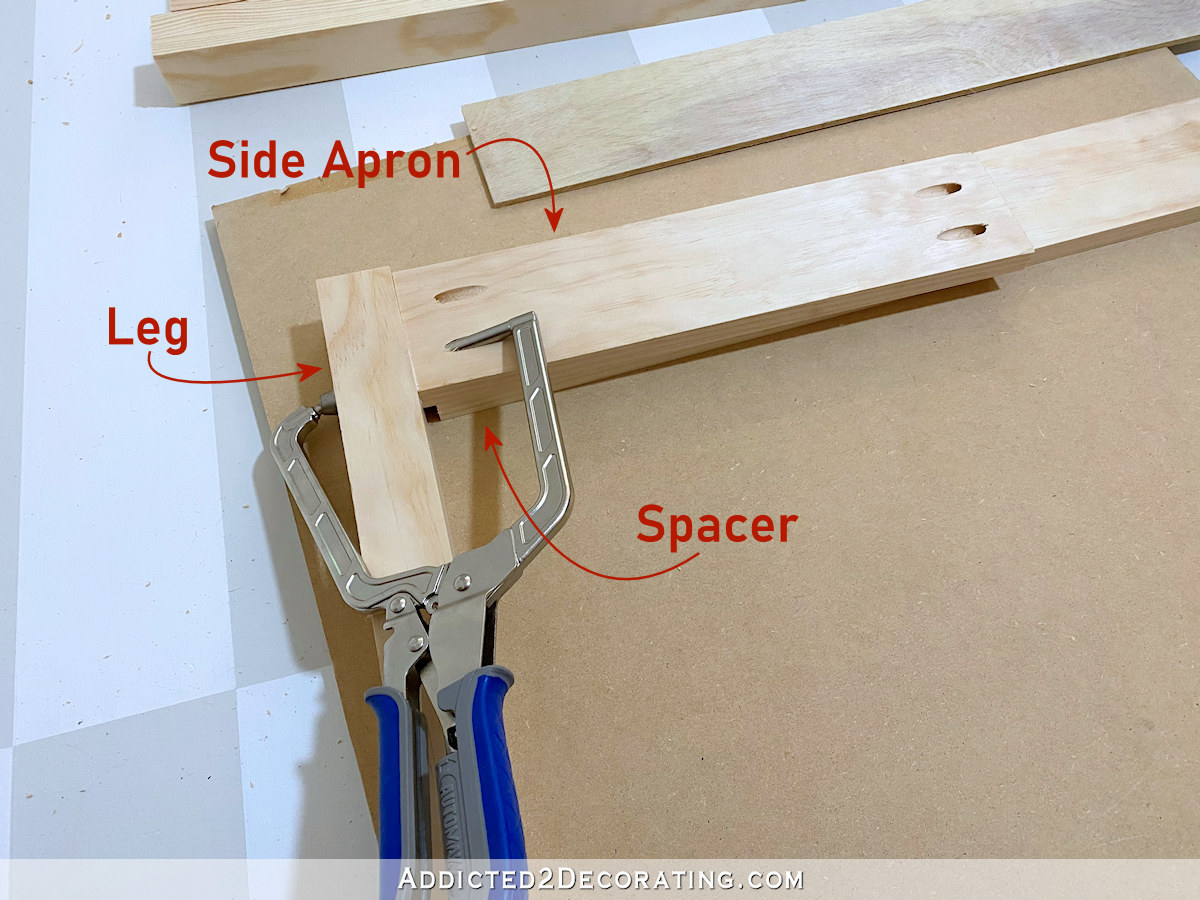

I assembled these pieces starting with the side frock. I placed wood mucilage on the end of the side apron piece, and so using a Kreg right angle clamp, I clamped the side frock slice to the leg. I similar aprons on tables and desks to be ready back a flake from the legs, so I used a slice of i″ x 4″ lumber (which is actually 3/4″ thick) equally a spacer under the side frock piece. With the pieces glued and clamped together, I screwed the pieces together using the pre-drilled pocket holes.

Then I repeated that process on the other side of that frock piece — mucilage, clamp, and screw the pieces together.

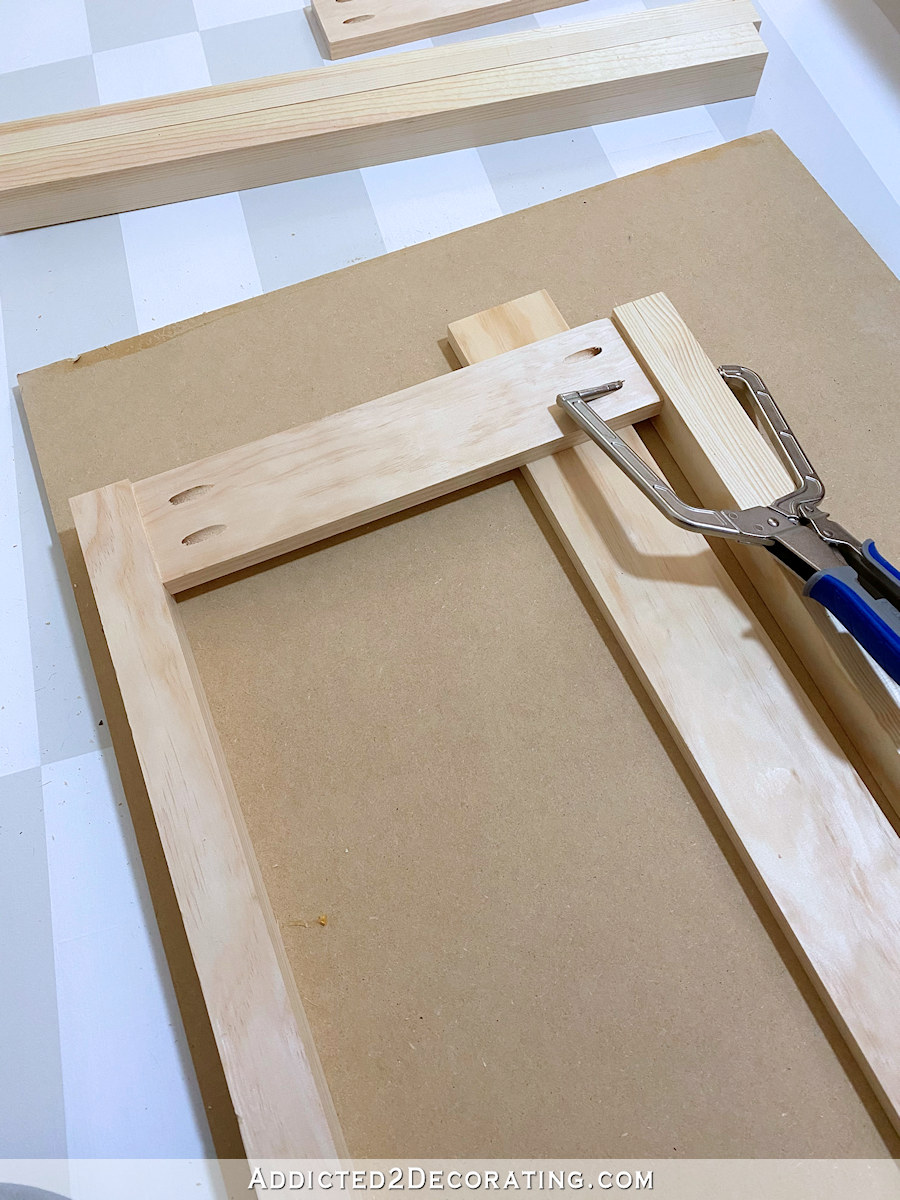

Here's what the back side (i.e., the side that would confront underneath the desk-bound) of that slice looked like once it was assembled…

And hither's what the front end side (i.e., the side that would be visible on the finished desk-bound) looked similar in one case assembled…

Next, I stood the assembled side slice up on its edge, and attached the back apron piece in the aforementioned mode, placing information technology on a i″ x 4″ piece of woods as a spacer before gluing, clamping, and screwing the pieces together…

After repeating that process on the other side, this is what the base of operations looked like at this indicate…

In gild to attach the two small stationary apron pieces on the front, I placed the desk-bound base on information technology's front…

And then fastened the small front apron pieces just like the others — spacer underneath, mucilage, clamp, and screw the pieces together.

With the two small front frock pieces fastened, it looked like this…

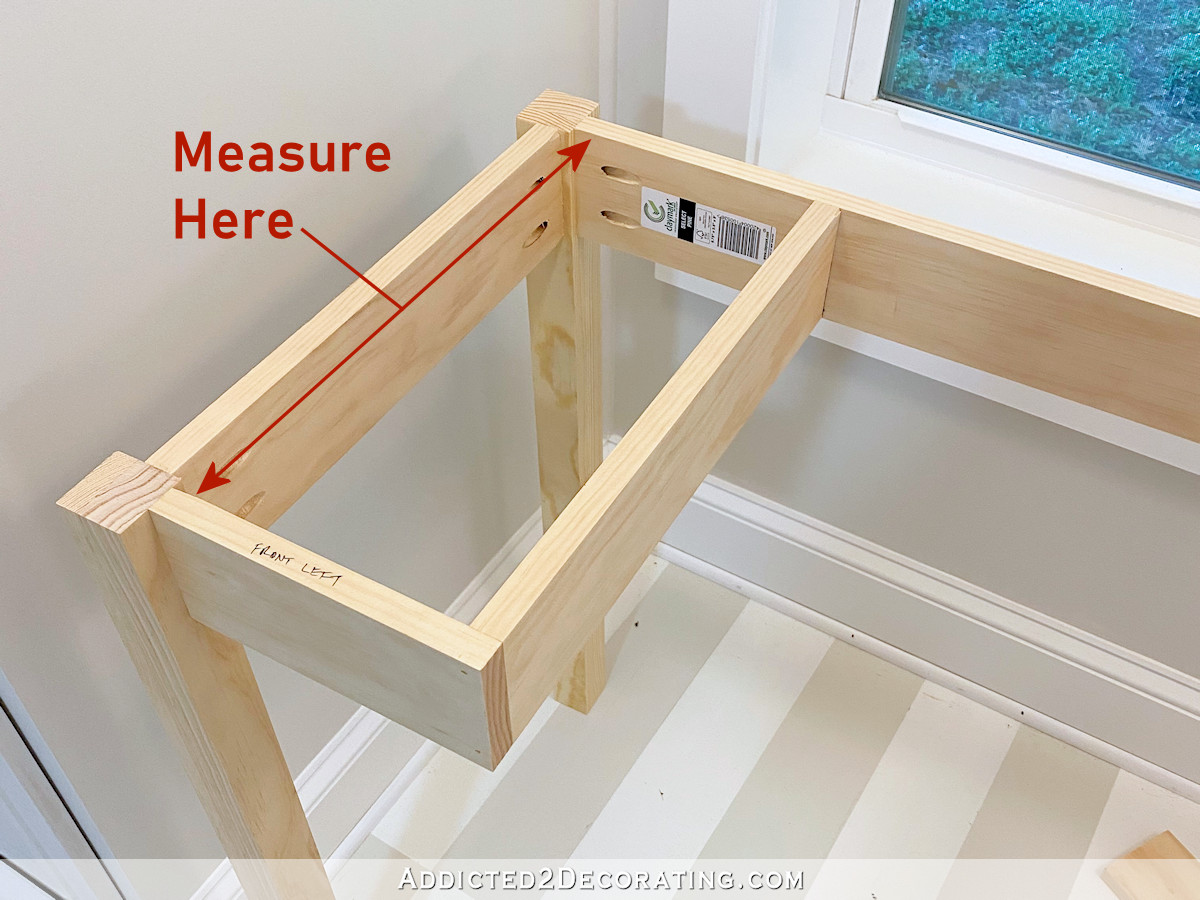

Next, I double-checked the measurement of the front apron piece…

And marked that same measurement onto the back frock piece…

And so subsequently measuring the distance between the front and back apron pieces (I took that measurement close to the legs)…

…I cut a piece of one″ x iv″ lumber to that length and attached it every bit shown below, using the mark that I had drawn on the back apron for placement.

To attach this piece, I used my sixteen-judge nail gun with 1 i/2-inch nails and just shot the nails correct through the front and back aprons into the edges of the piece.

I'll just apply a chip of forest filler to fill those holes before I paint or stain the desk. However, if you lot have objections to shooting nails through the front apron, you can attach this piece with pocket holes likewise.

After repeating that procedure on the other side, I was ready to cut and adhere the desk-bound top. However, it was at this point that I realized I had forgotten to drill the pocket holes to attach the top. So I had to go a scrap creative past attaching the Kreg pocket hole jig upside downwardly, and drilling the holes upside down. It wasn't really that big of a bargain. Information technology certainly would accept been easier had I remembered to do this before assembling the base, merely this worked out just fine.

Here you can see 4 of the nine holes that I drilled to attach the top.

And more on the other side. I also drilled some on the front frock pieces, which you obviously tin can't see in these photos.

How To Attach The Desktop To The Desk Base of operations

Adjacent, I used my table saw to cut a piece of 3/4″ plywood for the top. I cut the piece to 48″ x 20″. Then I placed it on height just to cheque for proper fit both on the base of operations as well as in the infinite.

To attach the top, I put the plywood face down on the floor, then placed the desk base upside down on the plywood and measured for placement. I measured to make sure the placement was just right, and and then I screwed the base to the top starting with the three center pocket holes on the back apron.

Before screwing the sides of the base onto the top, I used my framing square to check for foursquare. It'south imperative that this center section that forms the drawer well is perfectly square so that the drawer will function properly.

I repeated that on the other side until I had the base completely attached to the top.

How To Build The Desk Drawer

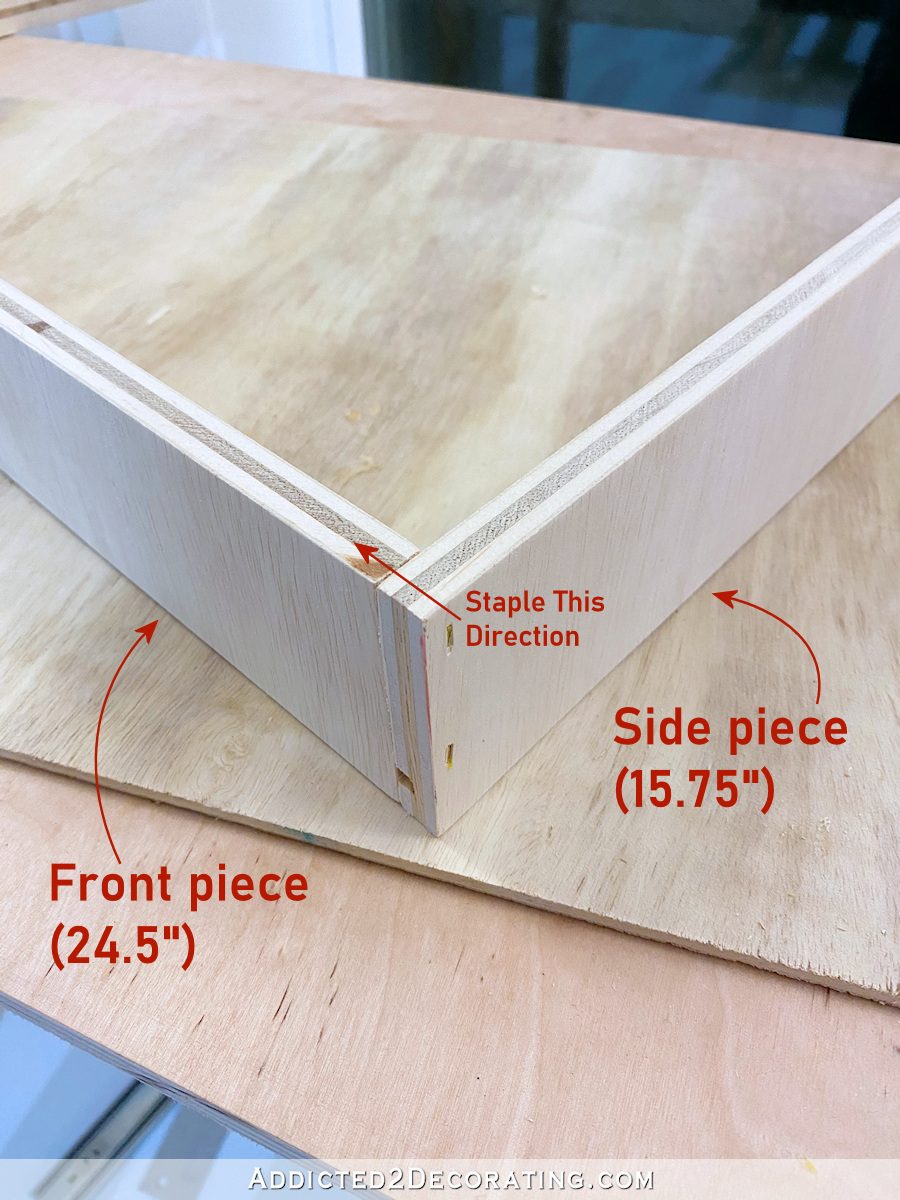

I used 1/2-inch plywood to build the sides of the drawer box, and using my table saw, I cutting the drawer sides 2.75 inches high. Then I used my miter saw to cut two pieces to the full depth of the drawer (fifteen.75″ for my desk-bound), and ii pieces to the width of the drawer well minus 2 inches (24.v″ for my desk). To become this measurement, you measure the width of the drawer well opening, and and so decrease the space needed for the drawer slides (generally i/2 inch for each slide, then ane inch total, but double check the specs on your particular drawer slides), and subtract the width of the sides of the drawer box (since I'yard using i/two-inch plywood, that is 1 inch for both sides).

Next, I ready my table saw and then that the blade was 1/4-inch high, and set the contend to iii/4-inch, and ran each slice through to cut the slots for the bottom of the drawer. This took three passes for each slice because later the first pass, I moved the fence over well-nigh ane/16 inch, and ran each piece through again. Then I moved the argue over some other one/16 inch, and did it a third fourth dimension. Information technology took iii passes to get the slot wide enough to accommodate the slice of 1/4-inch plywood that I would utilize for the drawer bottom.

I assembled these pieces using wood gum and 1-inch staples in my narrow crown staple gun, and I attached them then that the drawer box sides (i.e., the 15.75″ pieces) attached to the ends of the forepart slice.

When I had the front and two sides attached, I cut a piece of one/4-inch plywood to size (this took some trial and fault), and slid it into the slots…

And then I attached the dorsum drawer box slice using forest glue and staples.

To install the drawer sides, I couldn't use my standard method (i.e., using the Kreg Drawer Slide Jig) since there was no rail to clamp the drawer slide jig to. So I had to get artistic. Instead, I used a long slice of 1″ x iv″ lumber, and two clamps to hold the lumber merely to the bottom of the drawer bay side where the drawer slide needed to be fastened. That way I could identify the drawer side on the lumber and hands screw it into place.

This placement was very of import and had to be precise so that the drawer forepart would line upward perfectly with the small frock pieces on either side once information technology was attached. So I made certain that the forepart edge of the drawer slide was lined up equally perfectly as possible with the back edge of the front apron piece.

(Note: I used soft close drawer slides for this drawer, and on soft close drawer slides, the part that attaches inside the drawer well won't fully close until the role that attaches to the side of the drawer is attached. That's why you see that function sticking out most two inches in the picture to a higher place.)

I repeated that process on the other side of the drawer well, and with the slides fastened to the sides of the drawers, I was ready to install the drawer.

Hither's what information technology looked like with the drawer in place…

And finally, I merely needed to adhere that final front apron/drawer front end piece to the front of the drawer. I did this using three dots of hot glue and held it in place until it was dry and secure.

Afterwards the drawer front end was attached, I drilled the two holes for the knobs I'yard going to utilise for the drawer, and then I took the drawer out, took it to my table saw, and trimmed about one-half of a bract width from the elevation of the drawer so that information technology would open up and close hands without the peak edge of the drawer front touching the underside of the desk-bound top.

And finally, I finished off the edges of the plywood desktop by cutting some trim, mitered at the corners, and attaching those pieces with eighteen-gauge one-inch nails.

The trim that I used is 1 of my favorite get-to trims from Home Depot called chiffonier trim, and it'southward sold in whole viii-foot pieces (i.e., not sold by the linear foot). The trim is 7/eight inch, and the edge of the plywood acme is iii/4 inch, so I merely ran it through my table saw to cut it downwardly a fleck so that it would fit perfectly on the edge of the 3/4-inch plywood.

If the desk didn't have a drawer, I wouldn't accept bothered with cut the trim down. I would have simply used the trim in its original 7/8-inch land. Simply if I had used the 7/8-inch trim on the border of the iii/4-inch plywood on this desk, the front drawer wouldn't have been able to open up past the trim.

So that'southward the desk-bound so far. It'south actually such a uncomplicated build as long as you have the Kreg Pocket Pigsty Jig.

Fond 2 Decorating is where I share my DIY and decorating journey equally I remodel and decorate the 1948 logroller upper that my husband, Matt, and I bought in 2013. Matt has 1000.S. and is unable to practice physical piece of work, so I do the majority of the piece of work on the house by myself. You can learn more about me here.

I hope you'll join me on my DIY and decorating journey! If you desire to follow my projects and progress, you tin can subscribe below and have each new mail delivered to your email inbox. That way you'll never miss a thing!

edmondonlaceing1982.blogspot.com

Source: https://www.addicted2decorating.com/how-to-build-a-small-diy-writing-desk-with-drawer-part-1.html

0 Response to "Typical Drawer Box Installation for Small Desk Drawers"

Post a Comment